● Service Introduction

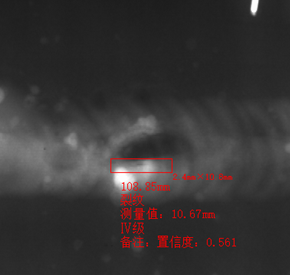

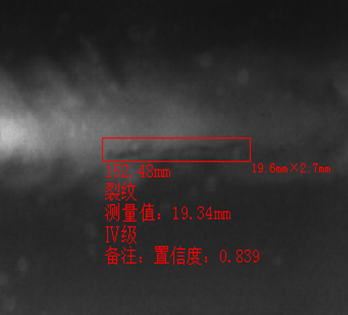

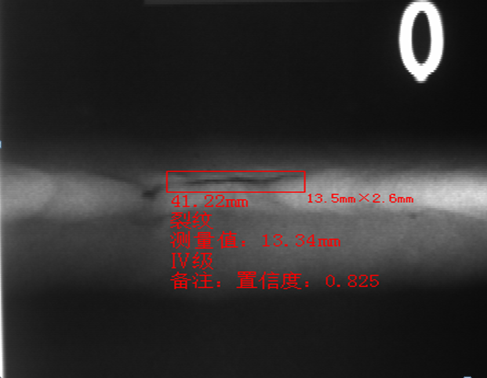

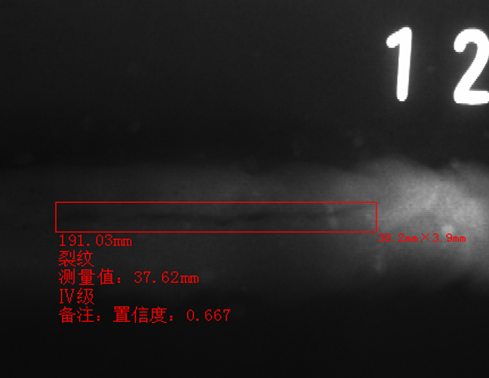

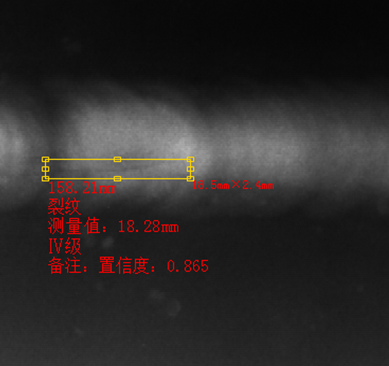

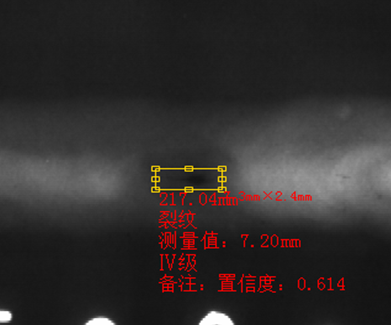

Intelligent Finding of Excessive Defects in Radiographic Imaging is an AI identification technology for timely detection of hazardous defects. The core is the intelligent identification technology of tiny cracks and substandard hazardous defects, which can be used to check the negatives that have been initially evaluated or re-assessed, and to find out the welded joints that have been missed or wrongly evaluated and have serious defects.

● the significance of the service

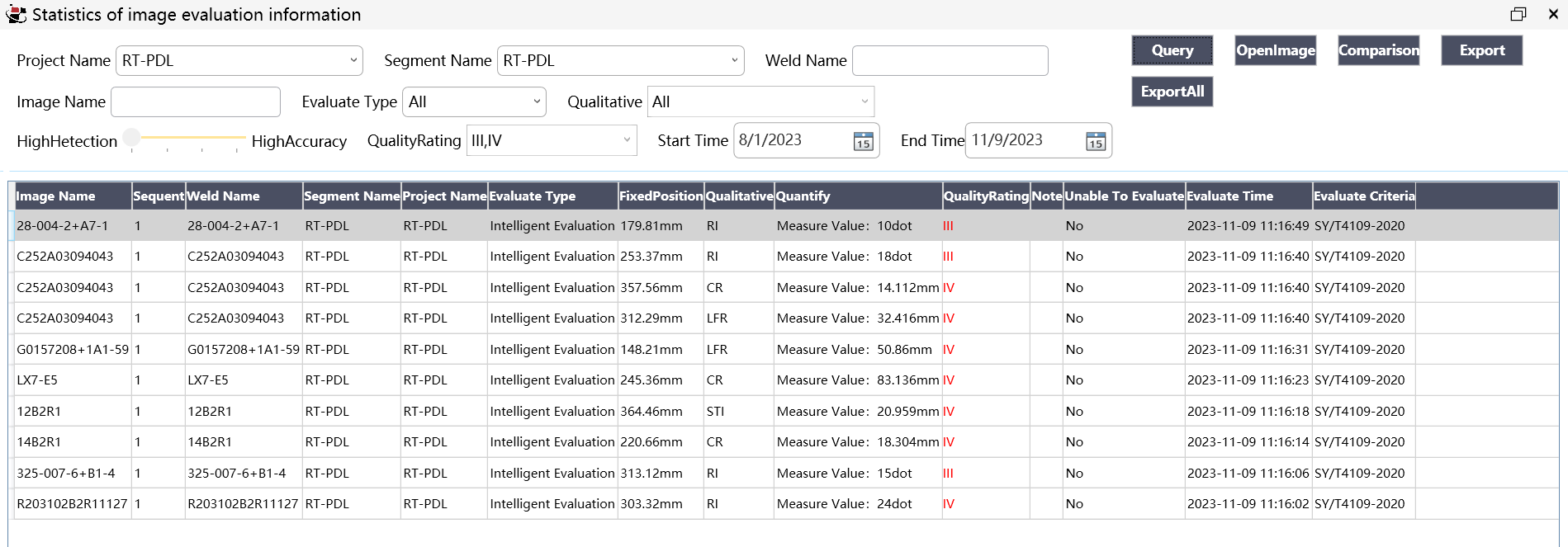

· Risk assessment of weld quality to identify potential safety hazards.

· Auxiliary personnel to assess the piece, easy to miss the assessment of the excessive defects to warn the characterization of defects prone to ambiguity, to avoid omission and wrong assessment

· Improve the efficiency of big data evaluation and reduce the cost of weld quality inspection.

· Provide data support for accurate maintenance and reduce maintenance costs.

· Reduces the burden of evaluators and reduces the intensity of heavy evaluation.

● Technical indicators

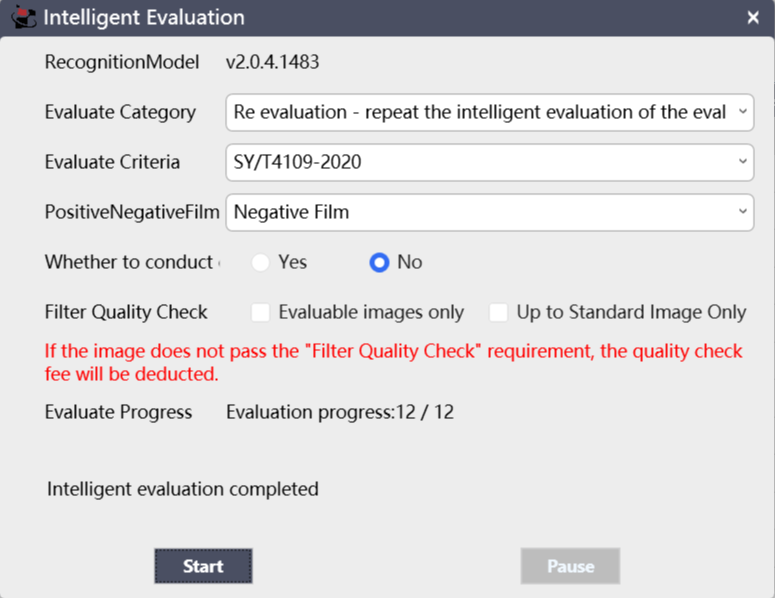

· Fast recognition speed, 100,000 pieces of film intelligent evaluation only 48 hours

· Detection rate of 95% for weld joints with serious defects that have been missed or incorrectly assessed.

· 98% accuracy in identifying serious defects against physical negatives.

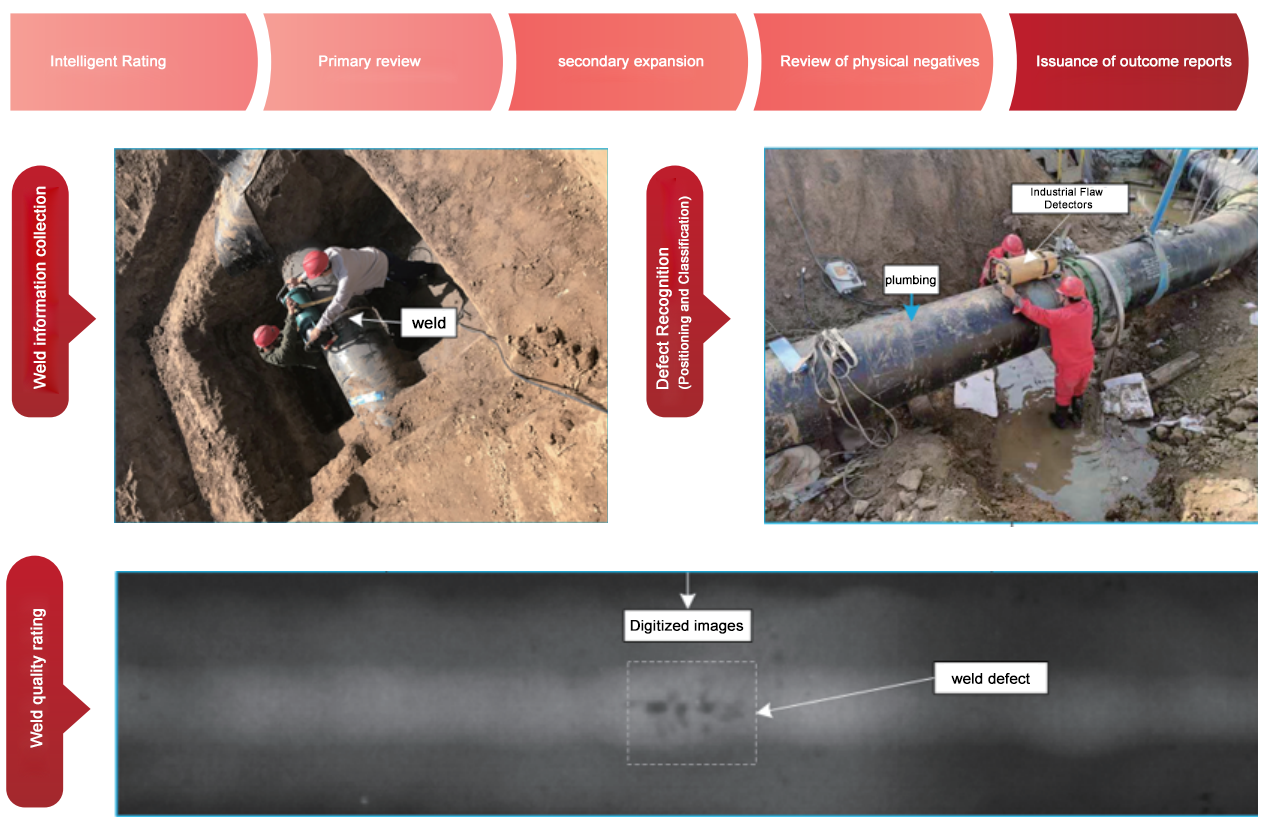

● Working methods and processes

Adopt AI intelligent recognition + manual review to review and analyze hazardous defects assessed by intelligence

● Find a Case