● Service Introduction

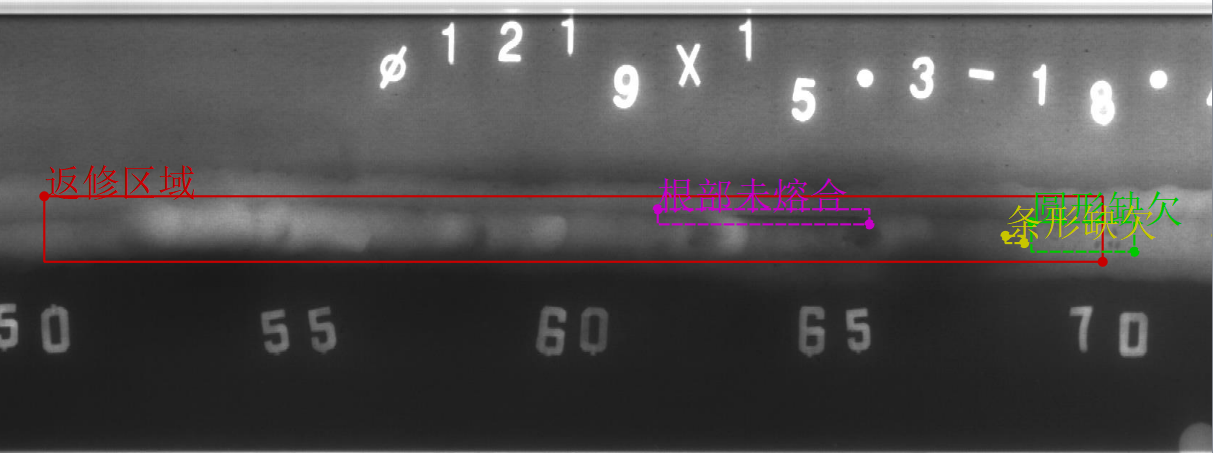

Through the big data intelligent analysis method to find out the non-controlled rework welded joints, and combined with the defect intelligent assessment technology and non-destructive testing engineers review, multi-directional in-depth investigation of weld safety hidden dangers, for the construction period of the project quality supervision or weld risk investigation to provide data support.

● Significance of Intelligent Finding and Hazard Analysis of Uncontrolled Reworks

· Real-time monitoring of uncontrolled rework weld joints for welding work in progress

· Risk screening of welds in constructed works

· Increased attention to uncontrolled reworked weld joints

● Technical indicators

· Uncontrolled rework area search accuracy 100%

· Recognition rate of unfused, cracked and striped defects in uncontrolled rework locations ≥95%.

· Non-destructive testing engineers to issue reports

● Find Scope

· Weld Rework Area Search

· Root fusion line abnormal weld bead search

· Search for defective weld bead in molding

● sort

· Effective constraints on uncontrolled rework by the builder

· Addressing the high volume of manual troubleshooting

· Quickly and efficiently identify potential safety hazards in welded seams

● Application Cases

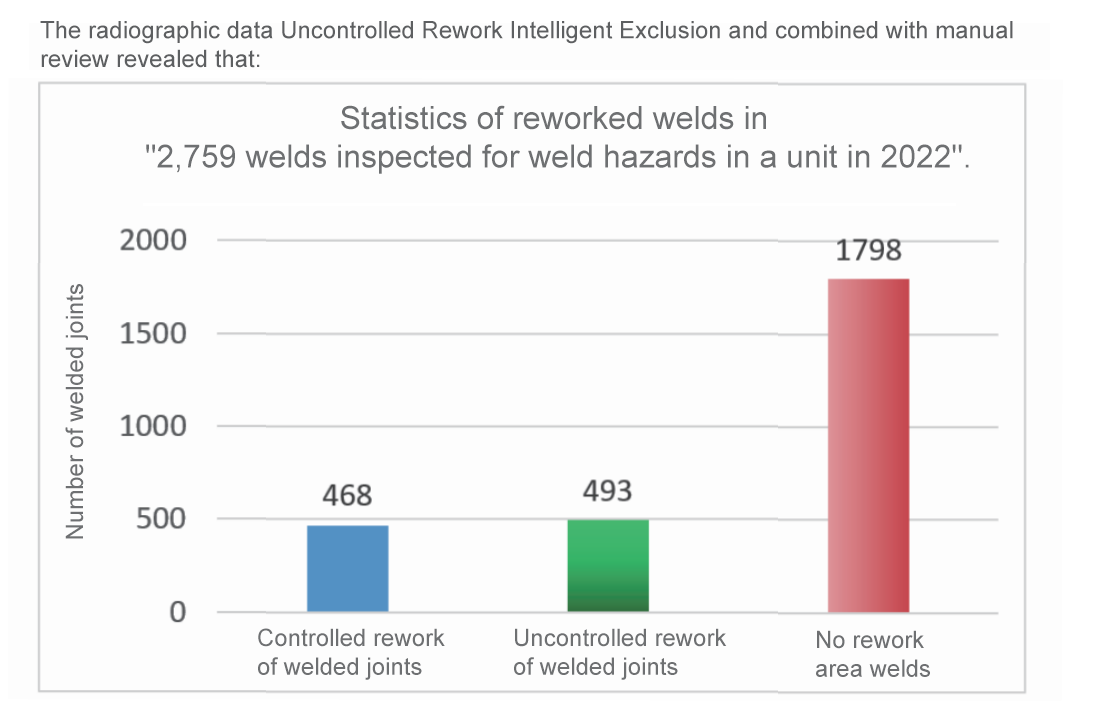

Data source: "3,500 welds from a unit's weld hazard inspection in 2022"

Intelligent identification software: radiographic uncontrolled rework intelligent screening system

Data base: 2,759 digitized construction-period negatives in 3,500 welded joints

Purpose: To find the uncontrolled reworked weld beads among 2759 weld beads.

Total time: 1 day Number of participants: 3 people